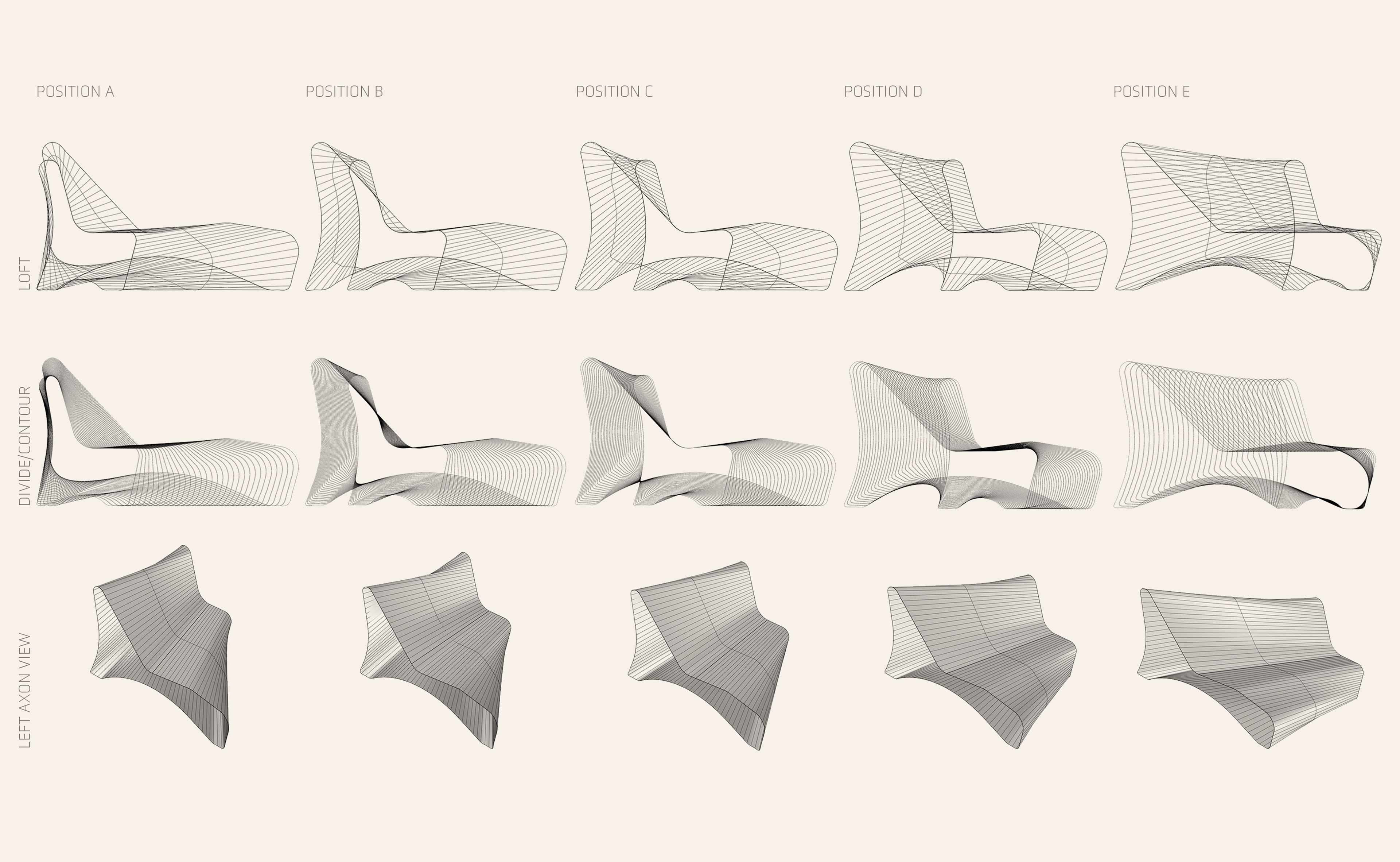

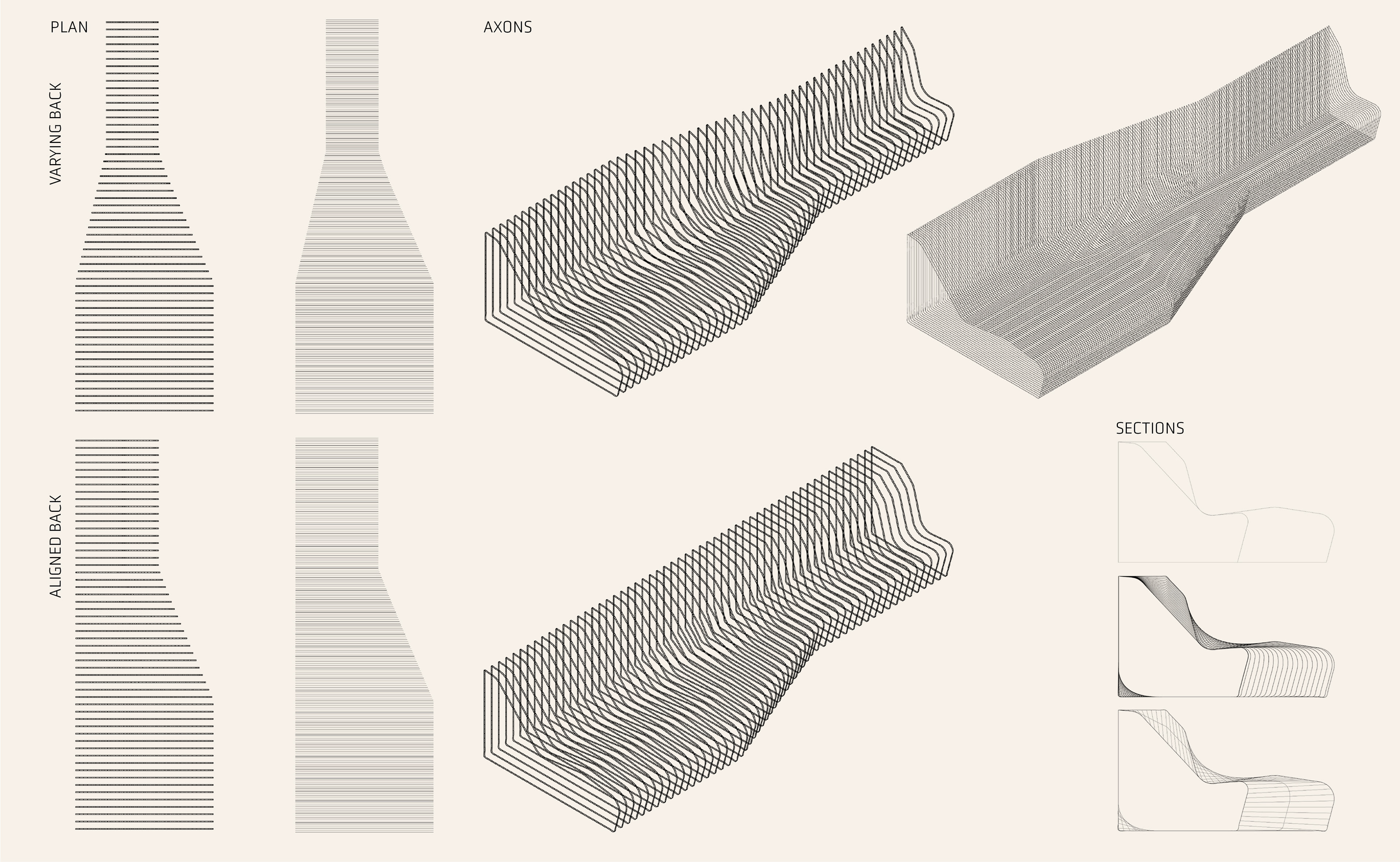

The bench ends were well-researched and drafted in AutoCAD. We imported the ends into Rhino and iterated the bench, altering the relationship between the two ends in elevation.

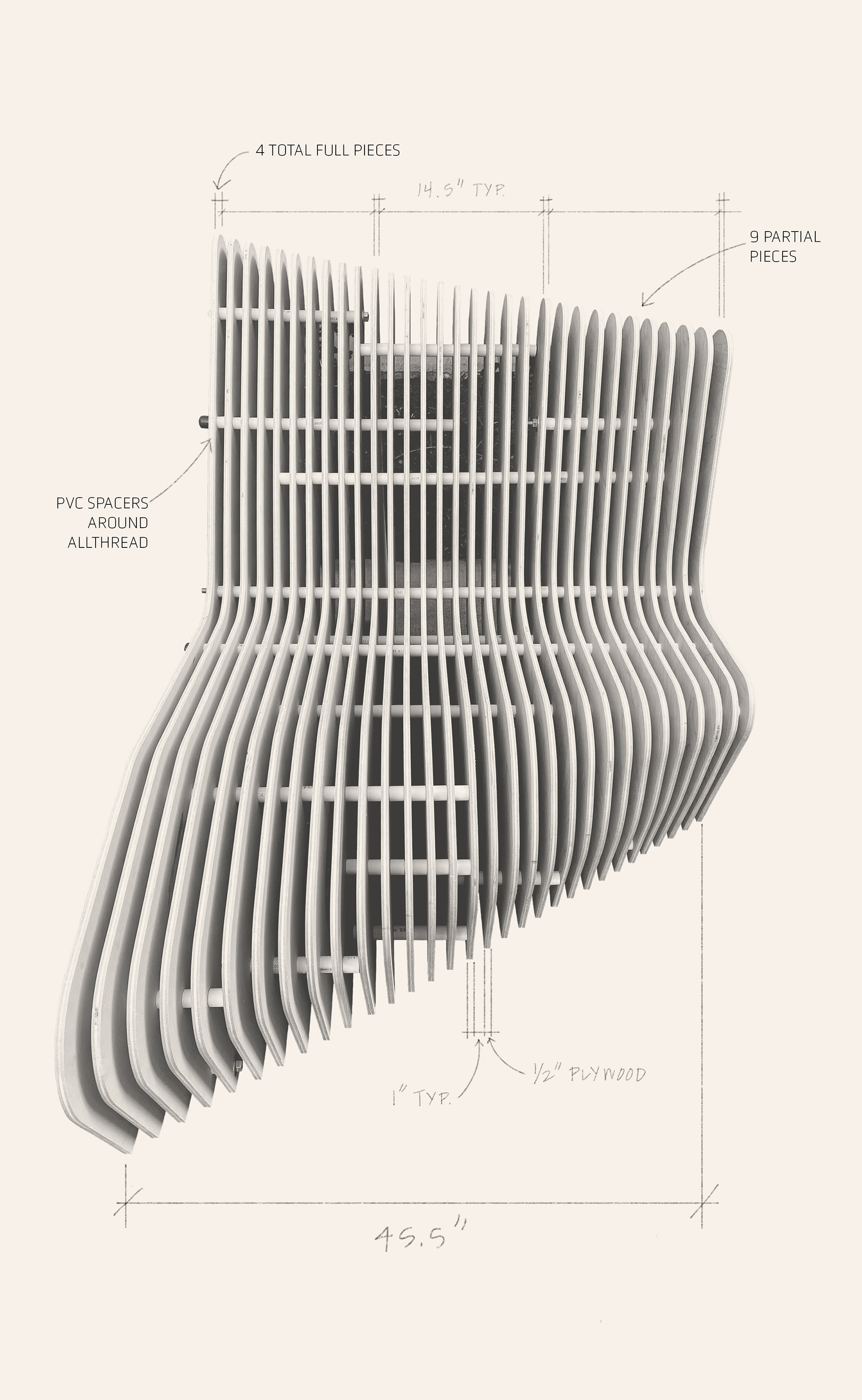

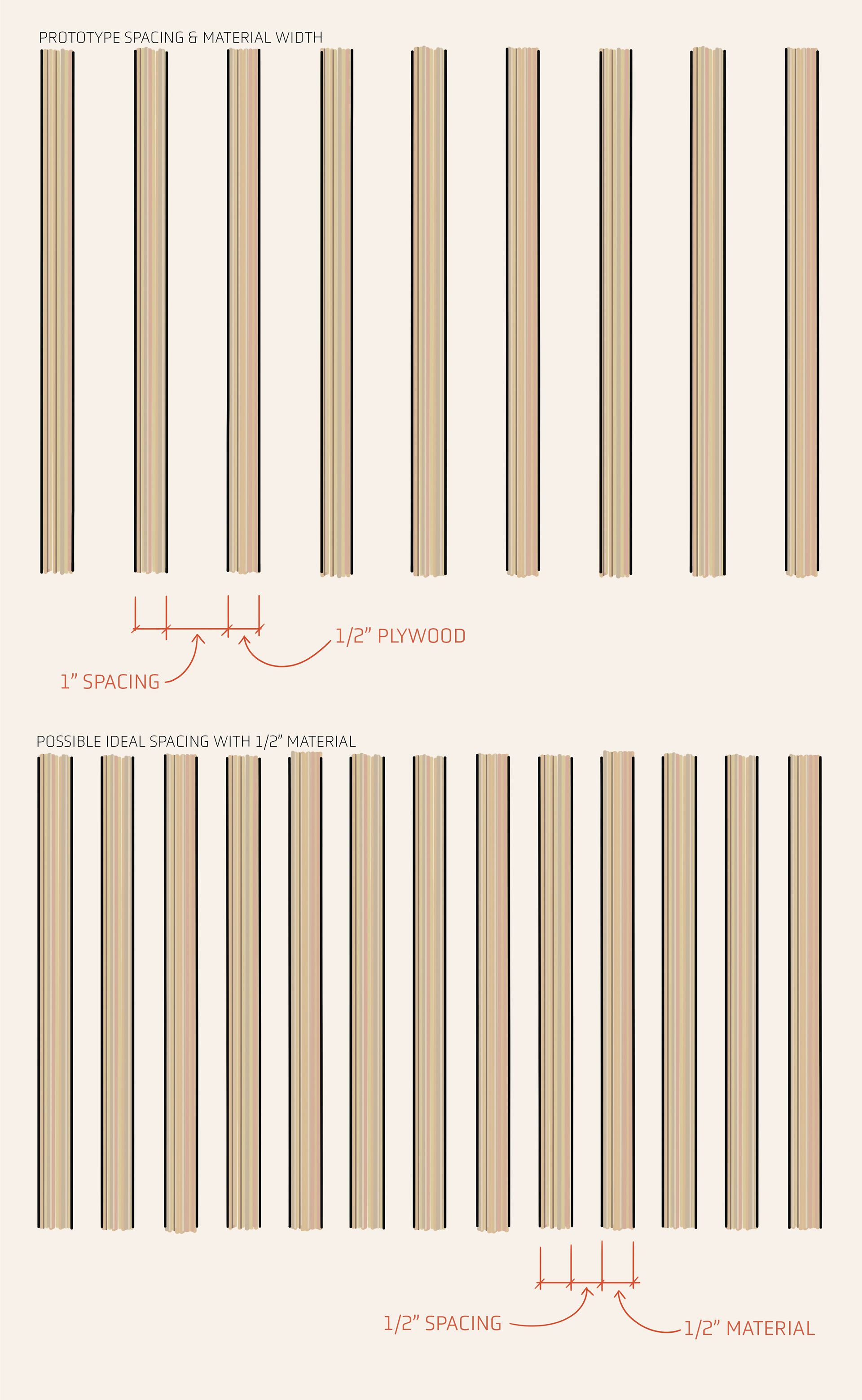

We were limited by our chosen material - 8, 4x8' sheets of 1/2" plywood. The prototype was made using a total of 31 pieces cut with the CNC. Four of the 31 were full-sized pieces. The rest were 6" wide strips that followed the seat edge.

The wooden pieces were spaced 1" (typ.) apart using cut PVC. Each piece had custom holes to allow for all-thread to pass through additional lengths of PVC. Nuts and washers were added to each end of the all-thread, holding the bench together in tension.

Collaborators: Darby Pierce & Jessica Gonzalez

PERSONAL WORK

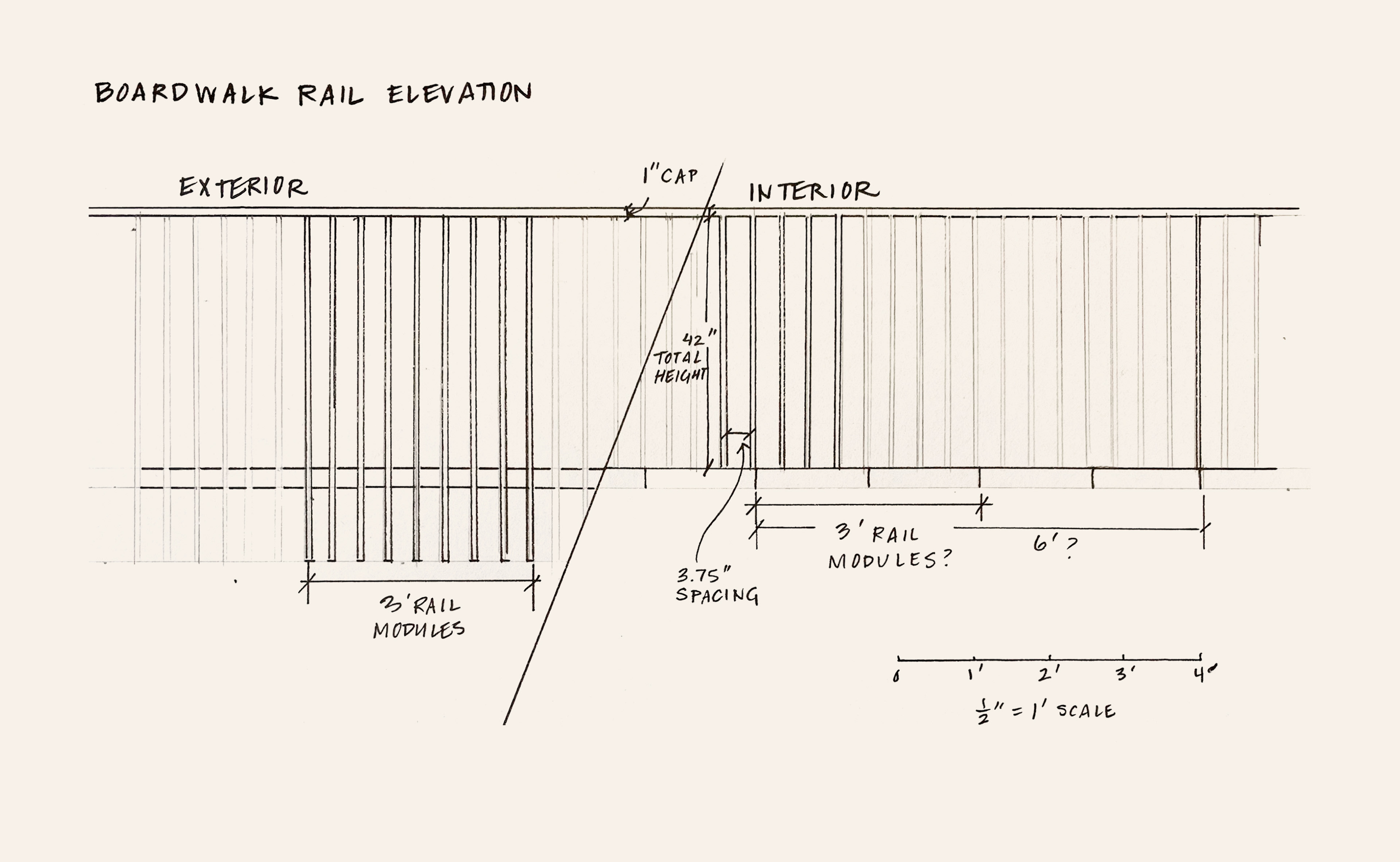

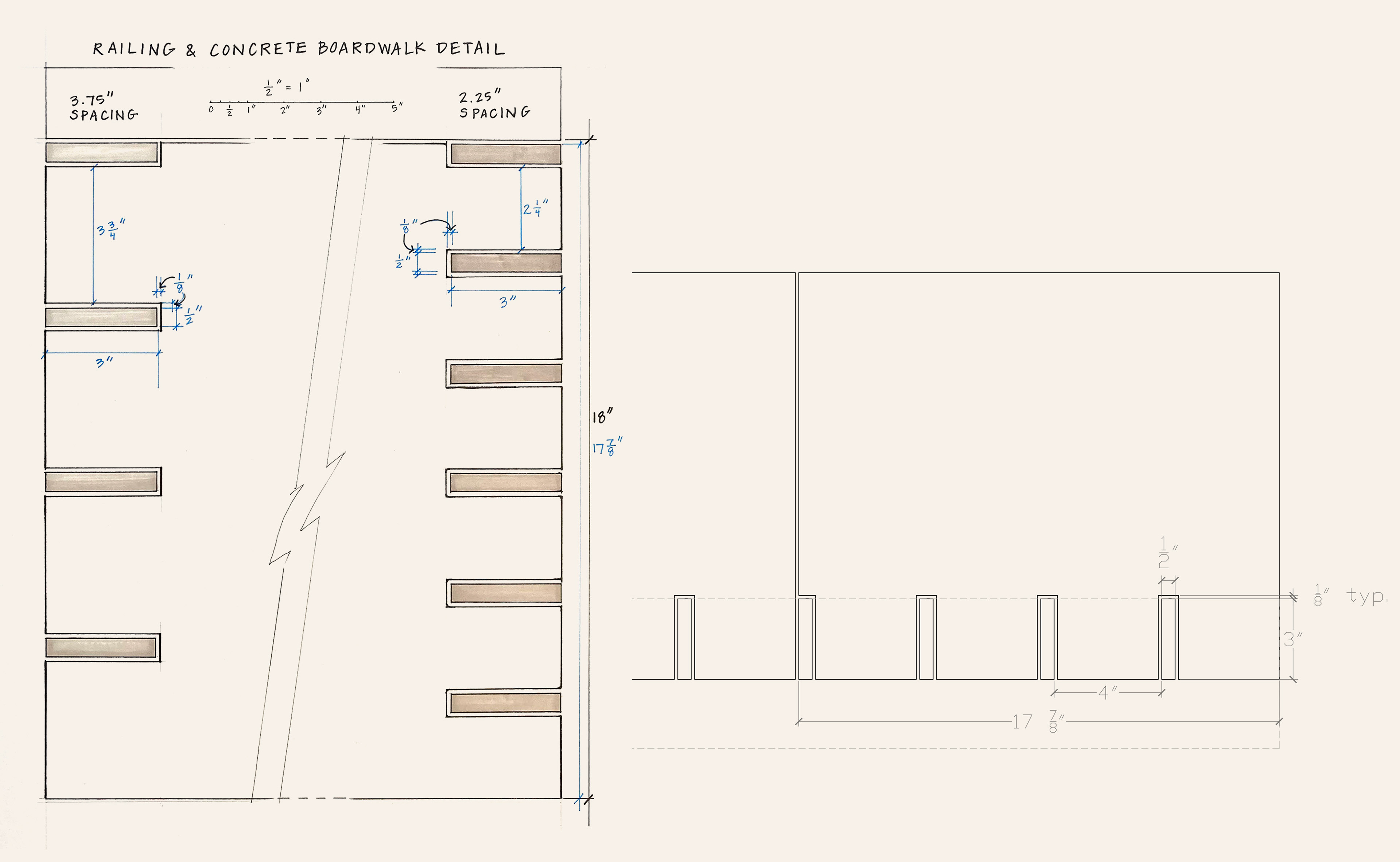

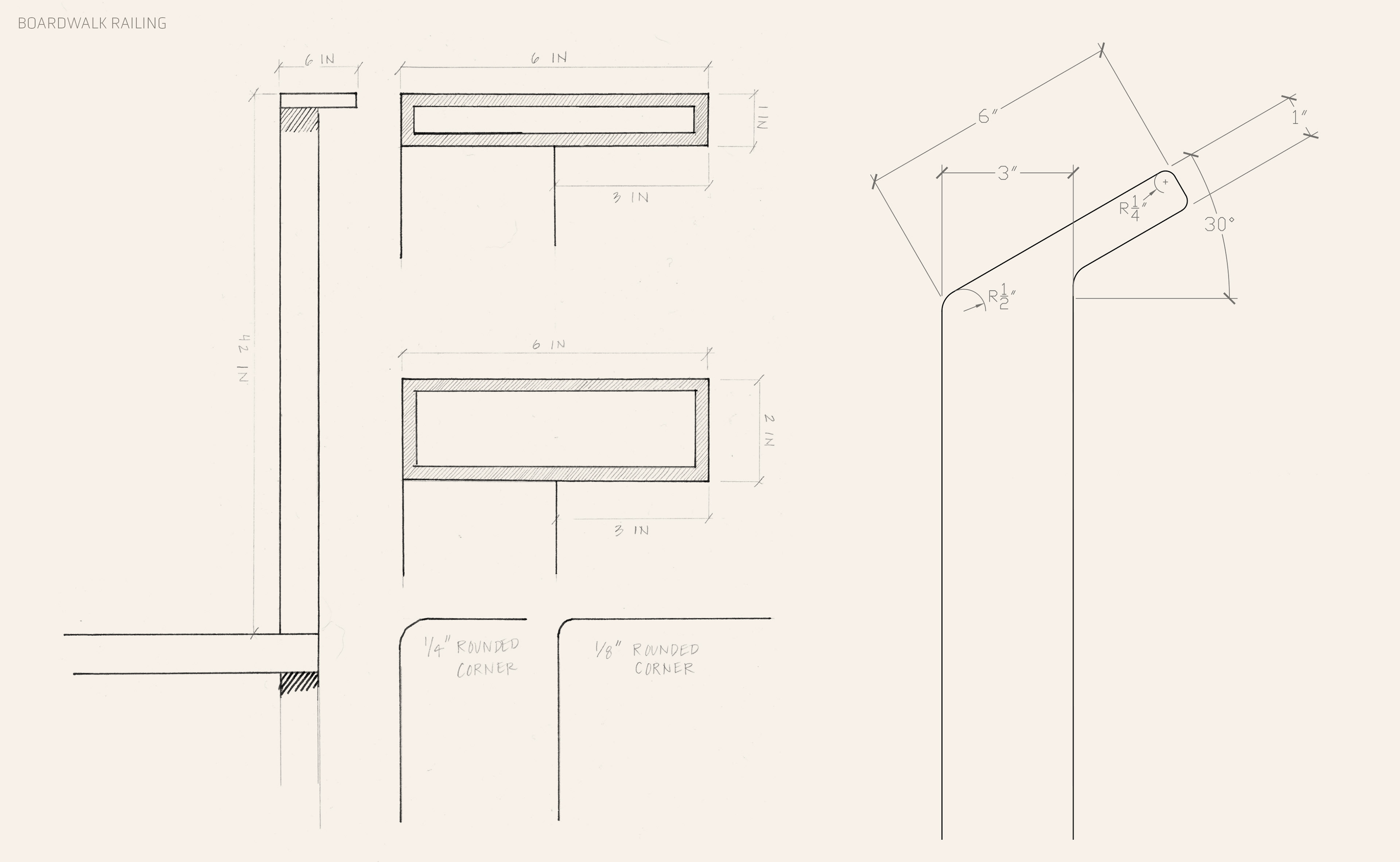

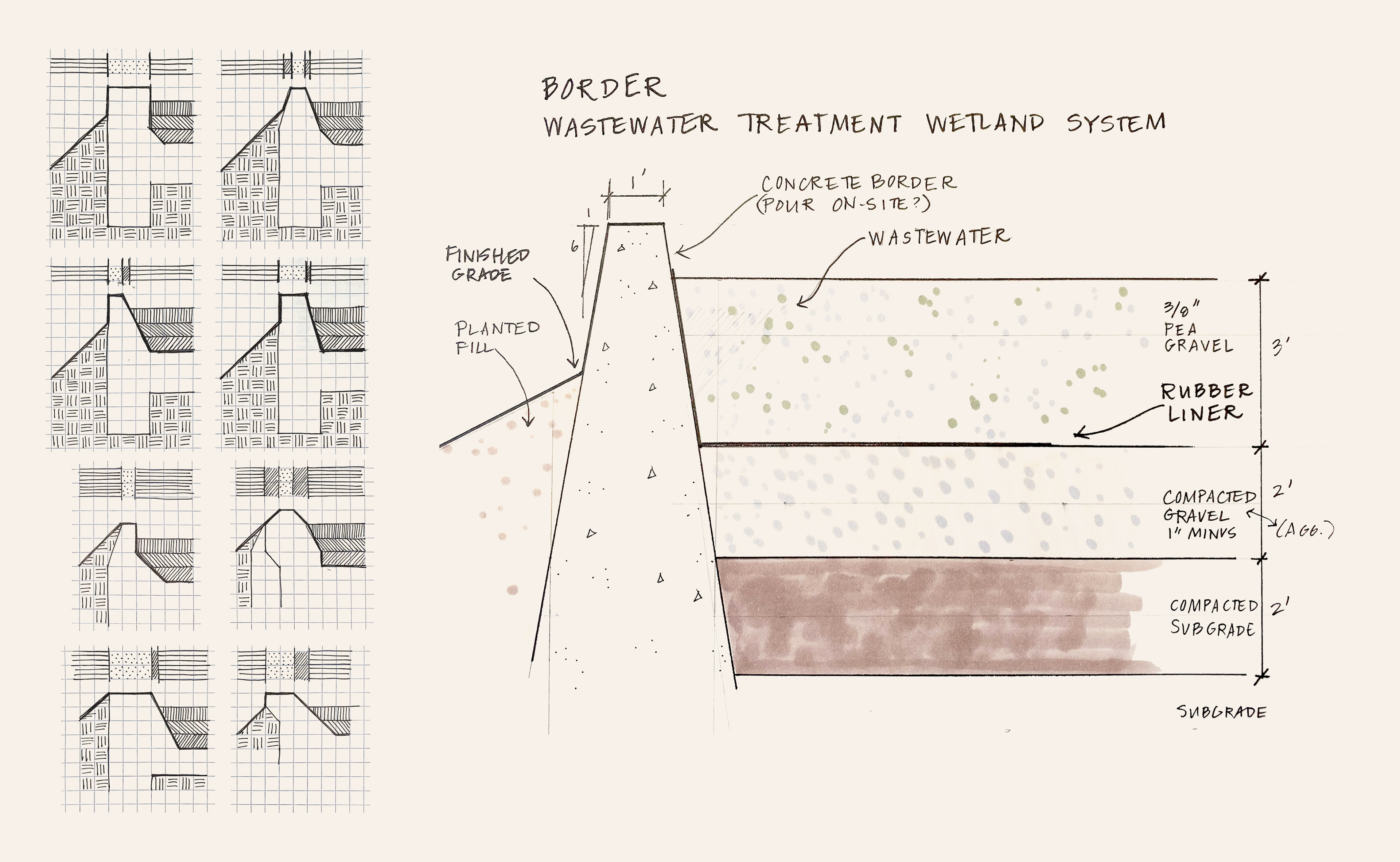

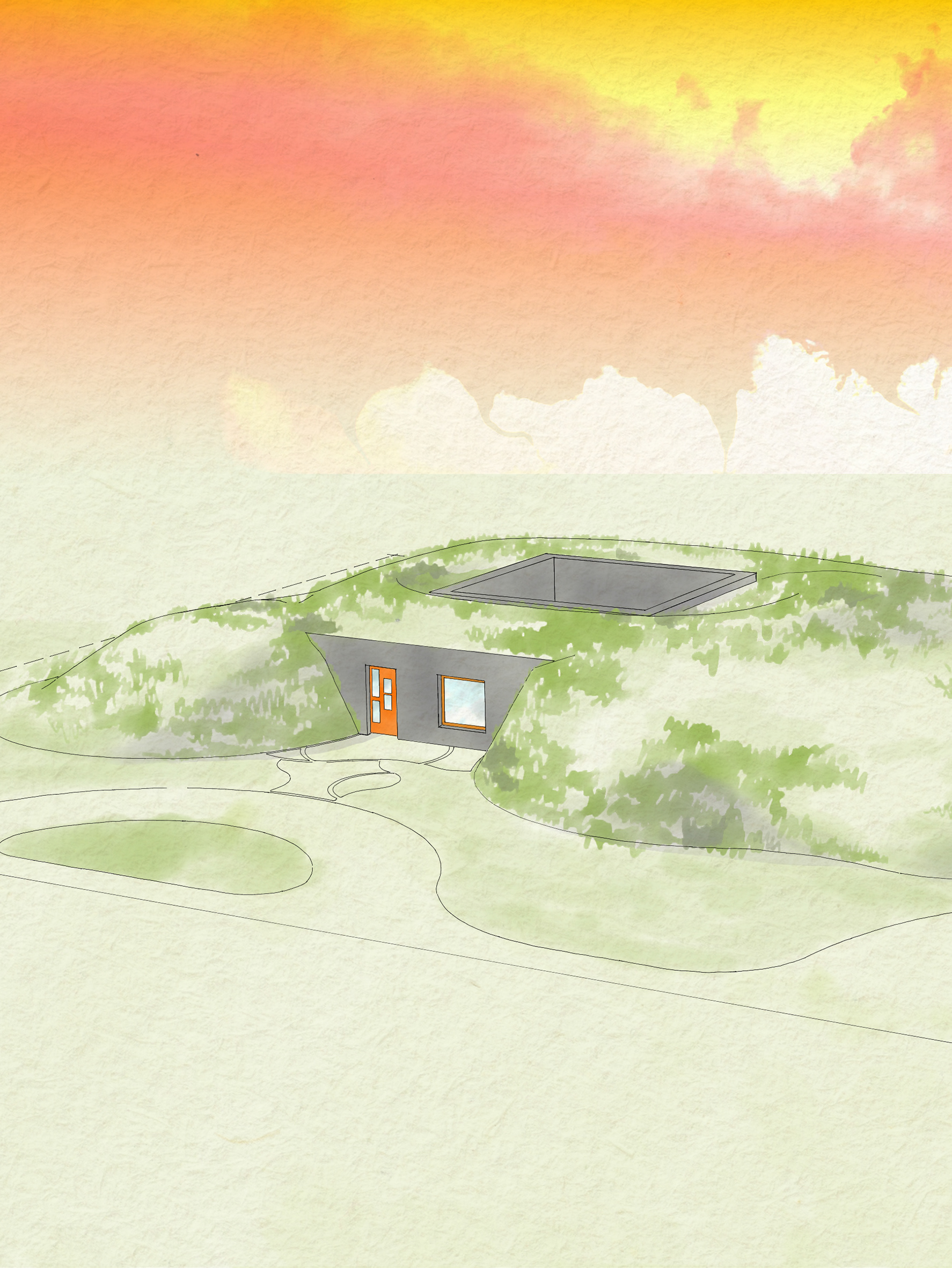

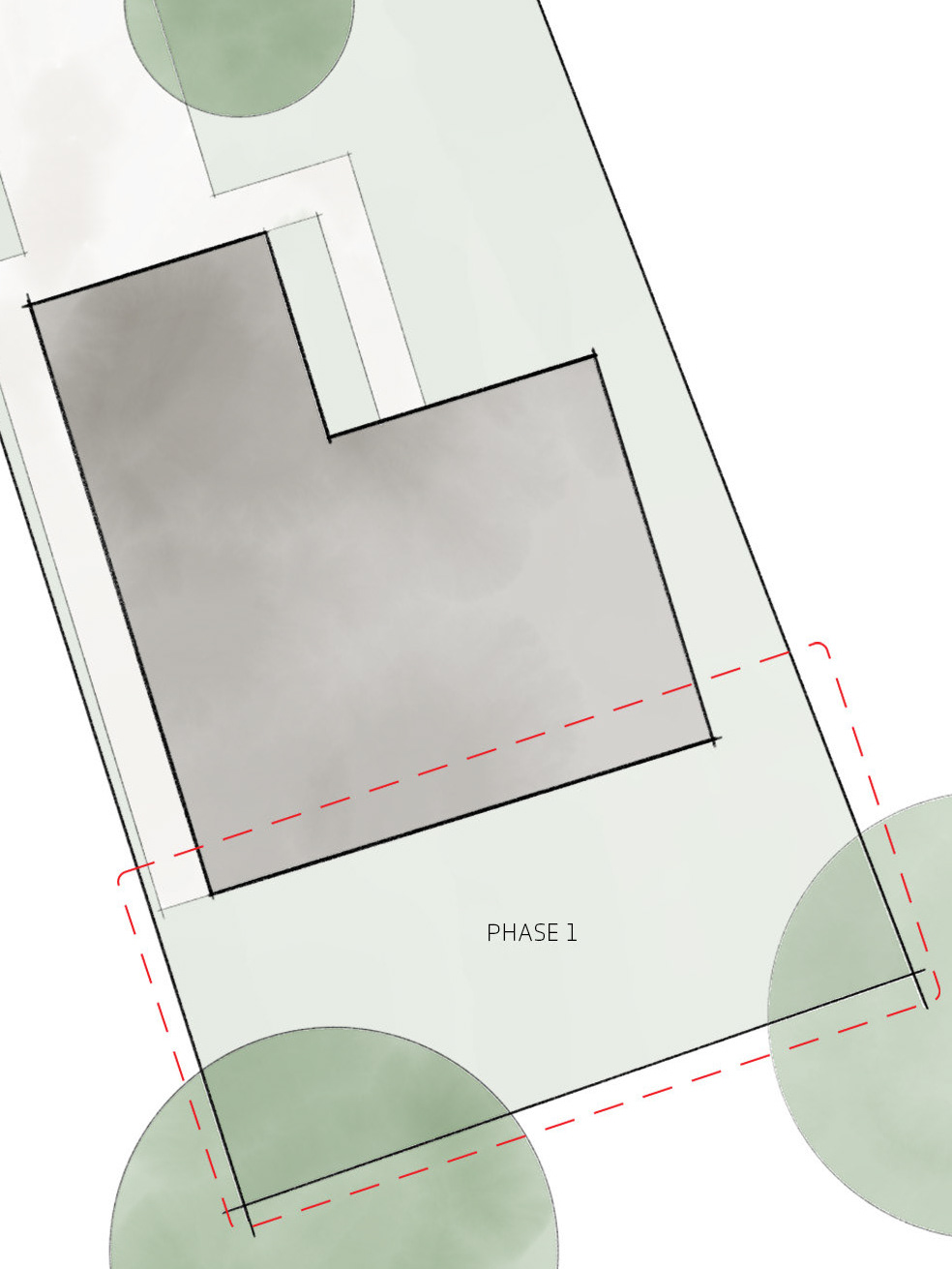

This studio was focused on technical landscape detailing. Each student produced technical drawings and details of part of their Vanport master plan; the selected area is approximately 120' by 40' in plan view. I chose part of my site where a housing sculpture would interact with the living water treatment system and feature a boardwalk.

I had been on the computer for school for over a year, so I took the opportunity to draft a majority of these by hand. I used AutoCAD later when designs were more finalized.

After the midterm, we grouped together based on common interests to develop a full-scale prototype.